Engineering

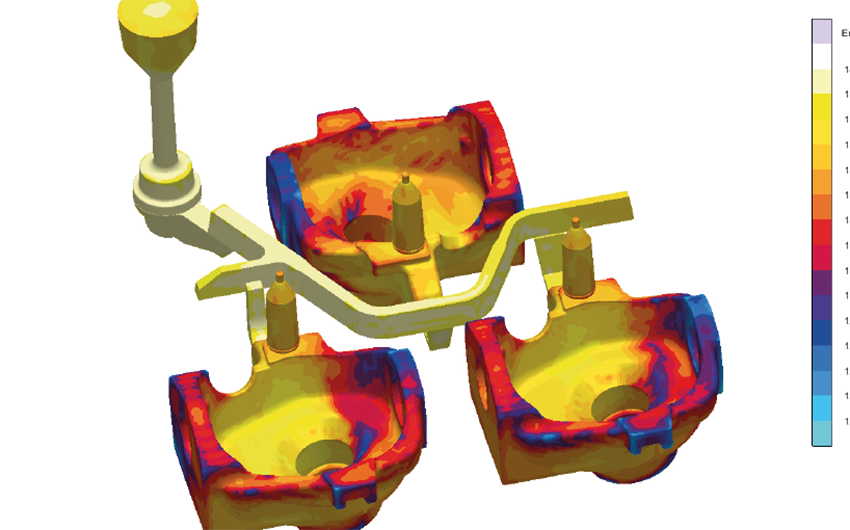

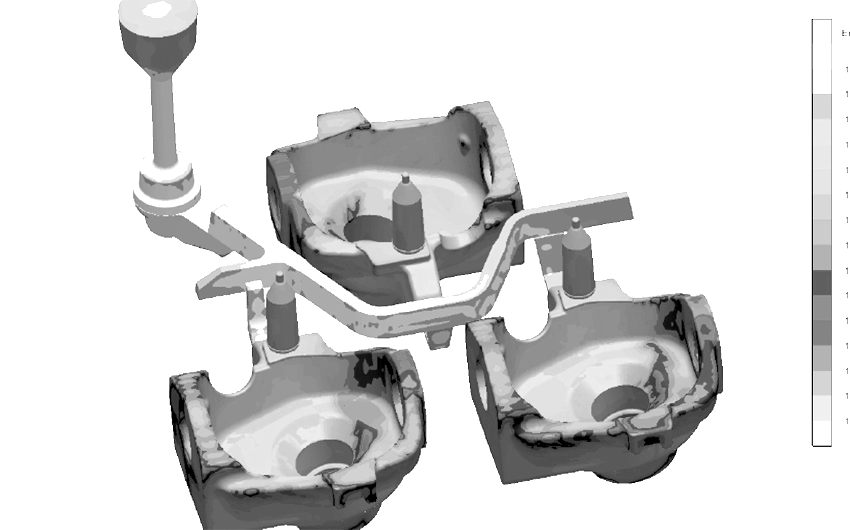

We have available an up-to-date engineering office, that uses the latest technological versions of CAD/CAM, melting simulation and solidification software. Engineering service is an effective tool at customer service. Optimization of sampling times, improving of production processes and focusing on possible critical situation and their solutions represent some of the clear advantages of this tool.

Equipment construction

Fonderie Glisenti set up a solid net of partners specialized in building equipment. Specialized technicians and machineries are daily dedicated to the service of Glisenti integrated process with a unique target: granting quality, punctuality and efficiency.

Controls

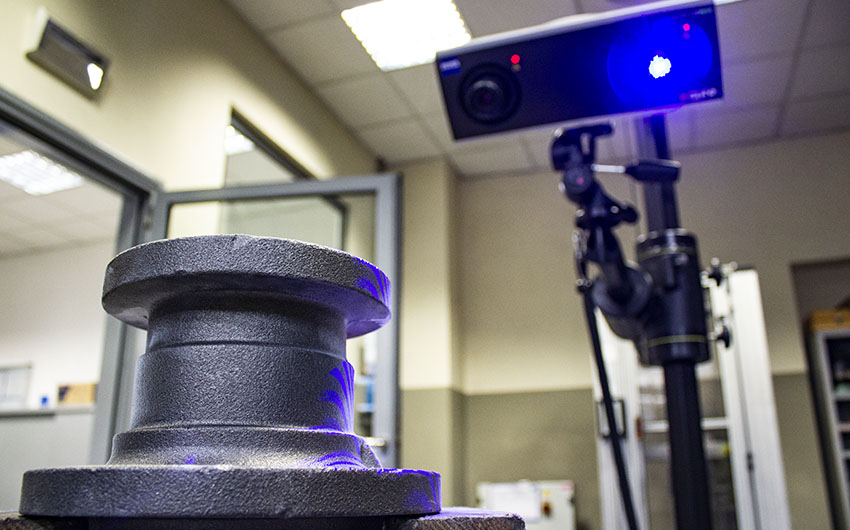

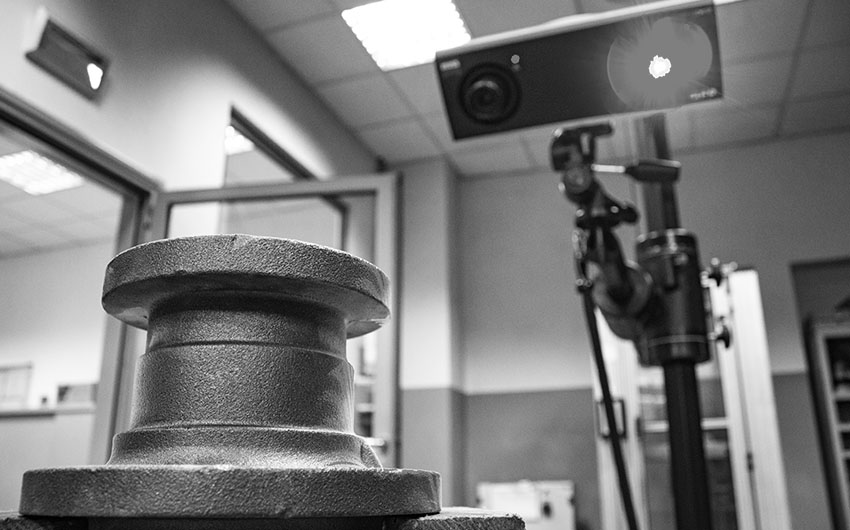

Metrology laboratory boasts a brand new measuring equipment with ZEISS optical scanning system with fringe projection COMET L3D 5M.

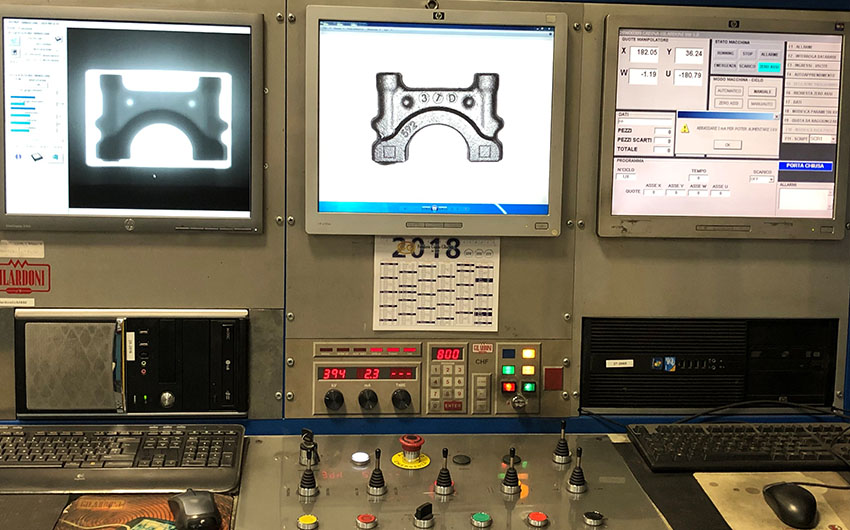

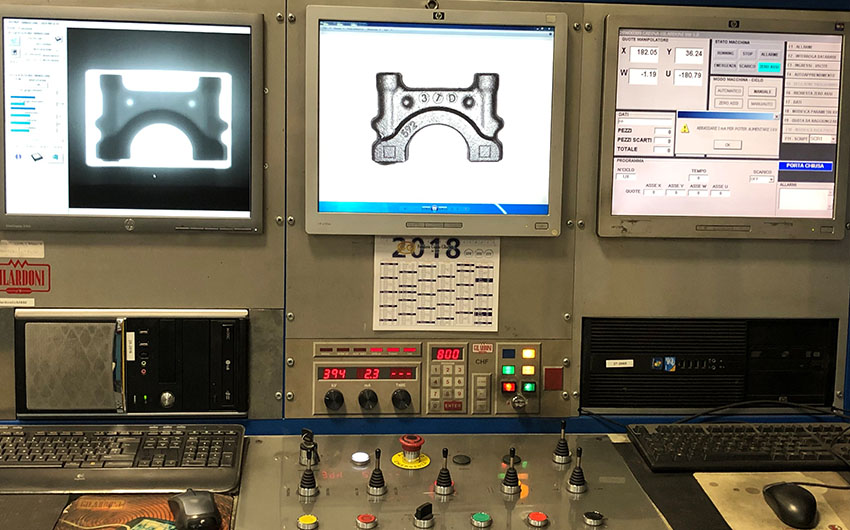

Not destructive tests

- QUANTOMETRIS

- THERMAL ANALYSIS

- MICROSCOPE analysis for structures control

- ULTRASOUND SPESSIMETRIS Gilardoni DG40

- ULTRASOUND AUTOMATIC CONTROL WITH IMMERSION PROBE

- Magnaflux

- RX IN BOX OF RADIOSCOPIC 450 KV

- DUROMETERS

- INSTRUMENT FOR RESISTANCE TO TENSILE STRESS

- INSTRUMENTS FOR electrical measuring

Machining management

Capability and technical competence characterize each phase of Glisenti machining operation on castings; partner companies and specialized technicians always grant maximum level of service. CNC milling and turning operations are performed on high technological profile machining tools and rigorous quality controls grant machining operation process.

After-sale service

Qualified Glisenti after-sale support always remains at customer’s service. Analysis capability, quick answers and problem solving attitude mark Glisenti after sales personnel.